Startup Inventory Mastery: Efficient Management Techniques

Table of Contents

Starting your own business is exhilarating, but it’s the smart moves in areas like inventory management that really set you up for success. As a startup, you’re not just juggling resources; you’re setting the stage for your future growth. Efficient inventory management is crucial, and getting it right can mean the difference between thriving and just surviving.

You know that every penny counts when you’re in the startup phase. That’s why optimizing your inventory processes is a game-changer. It’s not just about keeping stock levels in check; it’s about understanding your market, predicting demand, and minimizing waste. Let’s dive into how you can master inventory management to ensure your startup’s operations are smooth and cost-effective.

Understanding the Importance of Efficient Inventory Management for Startups

Efficient inventory management goes beyond merely knowing what’s in stock. It’s about striking the perfect balance between demand and supply, ensuring that your startup isn’t caught off guard by either surplus or deficit. Cash flow is the lifeblood of any new business, and inventory holds a substantial portion of your capital. You can’t afford to have funds tied up in excess stock, nor can you risk losing sales due to stock shortages.

When you neglect proper inventory control, the consequences can be severe. Overstocking can lead to obsolete inventory, taking up valuable space and capital that could otherwise be invested in growing your business. On the flip side, understocking might result in lost revenue and a tarnished brand reputation as customers face out-of-stock messages. By adopting effective inventory management practices, you’re better equipped to respond to market changes swiftly and with confidence.

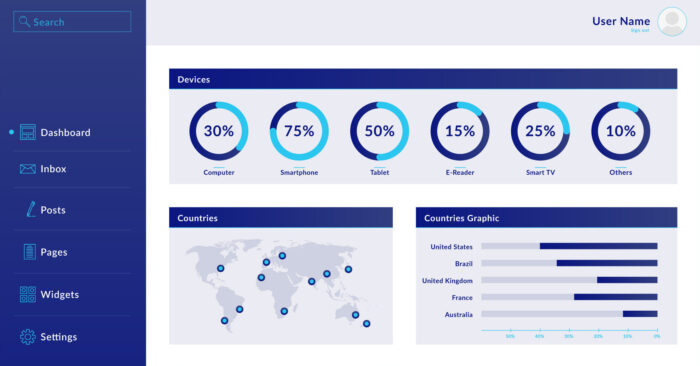

Real-time inventory tracking is a cornerstone of inventory optimization. Using technology to monitor your stock levels can prevent over-ordering and under-stocking. You should integrate inventory management software that keeps track of your stock and provides valuable insights into sales patterns. This real-time data empowers you to make informed decisions, such as identifying your best-selling products and adjusting orders to match demand.

Here’s why keeping an optimal stock level is crucial:

- Reduces carrying costs: Storage isn’t free, and excess inventory hikes up these expenses.

- Improves cash flow: Freeing up cash from unnecessary stock can be reinvested in other areas of your startup.

- Enhances customer satisfaction: Having the right products available when your customers need them boosts loyalty and trust.

Inventory management, particularly for startups, isn’t just about logistics; it’s a strategic imperative that impacts nearly every aspect of the business. From forecasting and procurement to sales and customer service, a well-oiled inventory system drives efficiency and growth. As you navigate the complexities of running a startup, remember that success often hinges on your ability to manage the smallest of details. Inventory management, while seemingly mundane, is one of those critical details that cannot be overlooked. It’s your silent ally in meeting customer demand and staying agile in a competitive market.

Assessing Your Inventory Needs and Setting Clear Goals

To manage your inventory effectively, you’ll first need to assess your startup’s unique demands. Your inventory needs are influenced by multiple factors such as product lifecycle, market trends, and consumer behavior. Understanding these elements ensures you maintain inventory levels that meet, but do not exceed, customer demand.

Your initial step should be to analyze sales data thoroughly. Look for patterns and trends that can inform your purchasing decisions. For example, if a particular product consistently sells well throughout the year, it’s a good candidate for higher stock levels. Seasonal items, on the other hand, require more careful planning to avoid costly overstock situations.

Once you’ve got a handle on the data, it’s time to set clear inventory goals. These goals should be SMART: Specific, Measurable, Achievable, Relevant, and Time-bound. Here are some examples:

- Specific: Identify which products you need to have more readily available.

- Measurable: Define the exact number of units you aim to sell over a certain period.

- Achievable: Make sure your targets are realistic given your sales history and growth projections.

- Relevant: Ensure that your inventory goals align with your overall business objectives.

- Time-bound: Set deadlines for achieving these inventory targets.

By setting SMART goals, you’ll be better equipped to adjust your inventory purchasing plans and align them with sales forecasts. This strategic alignment helps minimize holding costs and maximizes revenue potential.

Regularly revisiting your inventory goals is vital as market conditions and your startup’s situation evolve. By staying agile and responsive to changes, you’ll keep your inventory system optimized and ready to support business growth.

Remember, inventory management is not a set-it-and-forget-it task. It’s a dynamic process that necessitates continuous attention and refinement. Monitoring your performance against the goals you’ve set will be crucial. Adjust your strategy as needed to ensure you’re always moving closer to your optimal inventory levels.

Implementing Inventory Management Software to Streamline Operations

Imagine the simplicity and efficiency your startup gains with the right inventory management software in place. It’s not just about avoiding errors; it’s about integration and real-time insights that transform how you do business. By leveraging these tools, you’re equipped to make faster, more informed decisions that keep your stock levels in perfect harmony with demand.

Choose software that grows with your business, looking for scalability and customization options. It should be agile enough to adjust to changing market conditions and trends, something you’ve already learned is critical. Features like automatic reorder points, easy-to-understand analytics, and seamless integration with other systems, like your point of sale or accounting software, are worth their weight in gold.

- Streamline workflows

- Enhance data accuracy

- Improve demand forecasting

By automating inventory tasks, you reduce manual workloads and minimize human error. The software can alert you when it’s time to restock and even generate purchase orders for you, ensuring you’re never caught off guard by dwindling supplies.

Don’t forget to consider user-friendliness—the best software won’t do much good if your team finds it confusing. Look for options with a gentle learning curve and robust customer support to make the transition as smooth as possible.

Finally, real-time analytics arm you with a continuous, data-driven snapshot of your inventory. It’s not just about knowing what’s in stock—it’s about understanding your inventory turnover ratio, cost of goods sold, and having a clear view of your best and worst performing items. These insights enable you to pivot swiftly and smartly, a must for your startup’s longevity.

Implementing the right inventory management software isn’t a luxury, it’s a necessity for your startup. It streamlines operations, yes, but it also lays the groundwork for sustainable growth. The time and resources saved translate directly into more strategic opportunities and the potential for your business to scale with intention.

Forecasting and Demand Planning for Accurate Inventory Management

In the fast-paced world of startups, being one step ahead can make all the difference. That’s where forecasting and demand planning come into play. Accurate forecasting isn’t just a prediction; it’s a data-driven approach that helps you anticipate customer demand and plan your inventory accordingly. By mastering this, you can ensure that your startup maintains just the right amount of stock to meet customer needs without tying up valuable resources in excess inventory.

Begin by examining historical sales data. Look for seasonal trends, sales spikes, and any patterns that could influence future demand. This analysis should not only focus on quantity but also on which products are consistently popular and which are not. Advanced software solutions often include predictive analytics, letting you leverage algorithms and machine learning to refine your forecasts further.

Next, incorporate external factors that could affect demand. Elements like economic indicators, market trends, competitors’ actions, and even weather patterns can have a profound impact on what and how much your customers will buy. Keep these variables on your radar to tweak your predictions in real-time.

A crucial aspect of precise forecasting is the continuous feedback loop. Regularly compare your projections to actual sales to fine-tune your methods. Here are a few key metrics to monitor:

- Inventory Turnover Rate

- Stock-out Instances

- Carrying Costs

- Customer Satisfaction Levels

Remember, the goal is not just to have enough stock but to have the right stock. Through effective forecasting and demand planning, you can optimize your inventory levels to meet customer expectations while minimizing waste and reducing holding costs. Stay flexible and ready to adapt to changing market conditions, and you’ll keep your inventory lean and mean, just as a successful startup requires.

Adopting Just-in-Time Inventory Management Techniques

For startups looking to refine their inventory strategies, adopting Just-in-Time (JIT) inventory management techniques can significantly bolster operational efficiency. JIT is a strategy that streamlines your inventory system by aligning orders from suppliers directly with production schedules. The core philosophy behind JIT is that you hold no more inventory than what is necessary for immediate production or demand, leading to lower holding costs and a reduction in waste.

When you apply JIT principles, you’re primed to reap several key benefits:

- Less capital tied up in stock

- Minimized storage space requirements

- Improved cash flow

- Enhanced supplier relationships

Incorporating JIT requires meticulous planning and solid relationships with your suppliers. You’ll need to ensure they can fulfill orders on a tight schedule. Consistent communication with your suppliers is vital to synchronize the inflow of materials with your production needs. It’s crucial to have reliable suppliers that understand and adhere to JIT’s demands to avoid production delays that could hurt your business.

In order to start with JIT, you’ll want to:

- Evaluate your current inventory levels and determine the minimum necessary to operate efficiently.

- Collaborate closely with suppliers to shorten lead times.

- Integrate your inventory management software with JIT principles to facilitate real-time tracking and order processing.

It’s important to note that JIT is not without risks. A lack of buffer stock can lead to vulnerabilities should there be any disruptions in the supply chain. Therefore, risk assessment and mitigation are integral parts of implementing JIT in your inventory management plan. By analyzing historical data and predictive analytics, you can identify potential supply chain bottlenecks and create a contingency plan to maintain operation stability should unexpected challenges arise.

Minimizing Waste and Optimizing Stock Levels

Efficient inventory management plays a pivotal role in driving your startup’s profitability. Minimizing waste while optimizing stock levels is not just about slashing costs—it’s about smartly aligning your inventory with business goals. To achieve this, lean inventory techniques are your go-to strategy. These methods focus on reducing waste without sacrificing the quality or availability of products.

First, consider implementing a Kanban system—a scheduling system that controls the logistical chain from a production point of view, and is an inventory control system for lean and just-in-time (JIT) manufacturing. Kanban curbs overproduction, one of the key wastes in manufacturing, by pulling resources only on an as-needed basis. Here’s how it transforms your inventory management:

- Reduces excess stock and storage costs

- Enhances flexibility and responsiveness to demand changes

- Curtails overproduction and associated wastes

Next, it’s imperative to perform regular audits of your inventory. Physical inventory counts and cycle counting are methods that maintain accuracy in stock levels. Discrepancies caught early can prevent larger issues down the line. An accurate stock count ensures that your inventory data reflects actual on-hand quantities, enabling better purchasing decisions.

Inventory categorization—such as employing the ABC analysis technique—further sharpens your focus. This method categorizes inventory based on importance and value, with ‘A’ items being the most valuable and ‘C’ items the least. By doing so, you can:

- Align inventory management resources with the most impactful items

- Better forecast and manage stock levels across different categories

Dropshipping is yet another avenue to explore for minimizing inventory waste. With dropshipping, you only purchase the product from a third party when a customer makes a purchase, eliminating the need to hold large amounts of stock.

Adopting these tailored inventory management practices nurtures a lean operational model. This methodology not only streamlines your processes but also positions your startup to be more adaptive and competitive in rapidly changing markets. By leveraging real-time data and robust inventory management tactics, you’ll foster a dynamic system that scales with your business’s growth while keeping costs in check.

Conclusion

Mastering efficient inventory management sets your startup on the path to success. By leveraging real-time tracking and smart software, you’re equipped to balance demand with supply. Remember, it’s not just about having enough stock but having the right stock. Your ability to analyze sales data and adjust your strategies ensures you stay ahead of the curve. With techniques like JIT and lean inventory practices, you’ll minimize waste and optimize resources. Keep monitoring key metrics and refining your approach—your startup’s agility and financial health depend on it. Embrace these tools and strategies, and watch your business grow with confidence.

Frequently Asked Questions

What is the importance of inventory management for startups?

Efficient inventory management is crucial for startups as it helps balance demand and supply, preventing surplus or stockouts. It allows for optimization of resources and helps maintain cash flow by avoiding unnecessary stockpiling of products.

How does real-time inventory tracking benefit startups?

Real-time inventory tracking prevents over-ordering and under-stocking by providing up-to-the-minute data on inventory levels. This helps startups to make informed decisions quickly and keeps operations agile.

What are SMART goals in inventory management?

SMART goals in inventory management are objectives that are Specific, Measurable, Achievable, Relevant, and Time-bound. These goals assist in clearly defining targets for inventory levels and turnover, ensuring efficient resource allocation and performance tracking.

Why should startups implement inventory management software?

Inventory management software streamlines operations, automates tasks, reduces manual workload, and minimizes human error. It offers scalability, customization, real-time analytics, and can integrate with other systems, improving overall inventory efficiency.

What is the role of forecasting and demand planning in inventory management?

Forecasting and demand planning enable startups to anticipate customer demand and plan inventory accordingly. This optimizes stock levels, reduces waste, and minimizes holding costs by using historical sales data, predictive analytics, and considering external factors.

What benefits does the JIT inventory technique offer startups?

Just-in-Time (JIT) inventory management aligns orders with production schedules, which reduces inventory levels and waste. Benefits include less capital tied up in stock, minimized storage space, improved cash flow, and enhanced supplier relationships.

How can lean inventory techniques help startups?

Lean inventory techniques help startups minimize waste and optimize stock levels by implementing practices like the Kanban system, regular inventory audits, inventory categorization, and dropshipping. These practices streamline processes and allow startups to adapt and scale effectively.