Cut Maintenance Backlog: Prioritize Repairs to Prevent Downtime

Table of Contents

Managing your maintenance backlog can feel like a game of whack-a-mole. Just when you think you’ve got a handle on it, another issue pops up demanding your attention. But it’s crucial to stay ahead of the game to keep your operations running smoothly.

You know that downtime is the enemy of productivity. Prioritizing repairs and effectively managing your maintenance tasks ensures that downtime doesn’t derail your business. Let’s dive into how you can tackle that growing backlog and keep your systems up and running.

With the right strategies, you’ll not only clear that maintenance backlog but also prevent it from piling up again. Ready to transform your approach and boost your operational efficiency? It’s time to prioritize, plan, and execute maintenance like a pro.

Understanding the Maintenance Backlog

Before you can tackle the maintenance backlog effectively, you’ll need to understand what it entails. Typically, a maintenance backlog consists of all the scheduled maintenance tasks that have not yet been completed. These can range from routine check-ups to urgent repairs that directly impact your business operations. However, not all backlogs are the same, and understanding the nuances is crucial to managing them.

Categories of Maintenance Tasks:

- Preventive Maintenance: Scheduled activities aimed at preventing equipment failures.

- Corrective Maintenance: Unscheduled tasks that occur due to equipment breakdown.

- Inspection: Safety and compliance checks that need to occur at regular intervals.

Remember, maintenance tasks vary not only in type but also in urgency and complexity. Your first step is to assess the importance of each task. Some questions to ask yourself include:

- How critical is the equipment to your daily operations?

- What is the potential impact on safety and compliance if the task is delayed?

- What are the costs associated with immediate versus delayed repairs?

By categorizing and prioritizing your backlog, you’ll set the stage for a more streamlined process. Your goal should be to minimize downtime and ensure operational continuity. The longer a critical task remains on your backlog, the greater the risk to your operations.

The Ripple Effect of Backlogs:

Addressing your maintenance backlog isn’t just about fixing machines; it’s about understanding how unresolved issues can ripple through and affect various aspects of your business:

- Employee productivity: Workers are impeded by out-of-service equipment.

- Customer satisfaction: Delays in service delivery can tarnish your reputation.

- Overall profitability: Extended downtime means lost revenue and increased costs.

Smart Strategies to Address the Backlog:

To make a dent in your maintenance backlog, you’ll want to consider:

- Implementing a Computerized Maintenance Management System (CMMS) to track and prioritize tasks

- Allocating appropriate resources to address high-priority repairs

- Regularly reviewing and adjusting your maintenance schedule to prevent future backlogs

By employing these strategies, you’ll ensure that you’re not just reacting to a growing pile of maintenance tasks but are proactively preventing the backlog from impacting your business success.

The Impact of Downtime on Operations

When your maintenance backlog begins to snowball, it’s not just the growing list of tasks that you need to worry about—it’s also the unpredictable downtime that can strike at any moment. Downtime often results in halted production lines, idle workers, and, ultimately, significant revenue loss. Unexpected equipment failure is one of the leading causes of operational downtime, and here’s what you need to consider:

- Production Loss: Every moment your machinery isn’t operating, you’re missing out on potential output. This can mean missed deadlines, contract penalties, or lost opportunities.

- Increased Labor Costs: Technicians might have to work overtime to perform emergency repairs, and other employees might be forced to wait or do less productive work until systems are back online.

- Customer Trust: Consistent downtimes can erode customer trust and confidence in your ability to deliver on time, possibly leading to a damaged reputation and loss of business.

To truly understand the extent of downtime’s impact, consider this table encapsulating the average revenue loss businesses face:

| Industry | Average Revenue Loss Per Hour of Downtime |

|---|---|

| Manufacturing | $22,000 |

| Information | $14,000 |

| Finance and Insurance | $10,000 |

| Retail Trade | $4,000 |

Source: ITIC 2020 Hourly Cost of Downtime Survey.

It’s important to remember that these figures don’t just represent lost sales; they also include long-term consequences like reduced market share and increased costs associated with customer recovery efforts.

By proactively managing your maintenance backlog, you’re less likely to encounter unexpected failures leading to downtime. A strategic approach involves regular equipment inspections and preventive maintenance. Properly prioritized, this can help ensure the most critical systems are always up and running, minimizing the impact on your operations should a less critical system encounter issues. Additionally, a CMMS can provide real-time visibility into asset conditions, ensuring that you’re one step ahead of potential failures.

Prioritizing Repairs: Where to Start?

When your operations face a mounting maintenance backlog, knowing where to begin can be overwhelming. The key to streamlining your efforts is prioritization. Not all repairs are created equal, and understanding which issues to tackle first can significantly reduce downtime and save costs.

Start by assessing the criticality of each piece of equipment. Equipment that is vital to your operations should be top of the list. Ask yourself which machines have the highest impact on production, safety, and revenue generation. Break down your equipment into categories:

- High priority: Essential for daily operations

- Medium priority: Important but not critical

- Low priority: Equipment that can withstand longer waiting times

Safety issues should never be overlooked. Any maintenance work that addresses potential hazards must be considered a top priority. Neglecting these can lead to severe consequences, including legal liabilities and harm to staff.

Next, analyze the costs associated with each repair. Consider both the direct costs of the repair and the indirect costs of continued operation with a malfunction. There may be hidden expenses like increased energy consumption or secondary damage caused by a malfunctioning part. Some questions to weigh include:

- What is the cost of the repair versus the cost of replacement?

- How does the malfunction impact energy efficiency?

- Are there any risks of secondary damage?

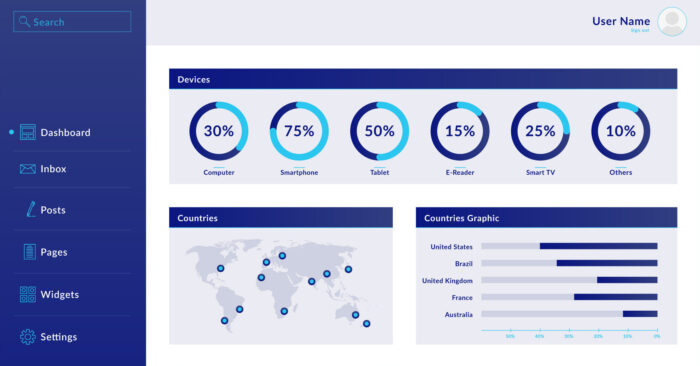

Using a Computerized Maintenance Management System (CMMS) can help organize and prioritize tasks. Digital prioritization allows for a clear overview of maintenance needs and the ability to quickly adjust priorities as conditions change. With CMMS, you can factor in elements like:

- Work order history

- Downtime incidents

- Repair costs

In the end, your goal is to create a dynamic and responsive maintenance schedule that avoids the pitfalls of reactive maintenance. Minimize downtime through strategic prioritization and keep your operations running smoothly by addressing the most pressing issues first.

Creating a Maintenance Plan

When dealing with a backlog, your first step is to formulate a comprehensive maintenance plan. This plan will act as your roadmap, guiding you through which repairs to tackle first and which ones can wait. A well-structured maintenance plan is invaluable, allowing for both preventive measures and timely responses to urgent issues.

Assess the Urgency and Impact of each equipment issue. You’ll want to use a systematic approach to evaluate how each malfunction affects operational safety, production efficiency, and revenue. Break down your equipment into categories based on their criticality and sort by:

- High-risk equipment

- Revenue-critical machinery

- Less critical assets

By doing so, you establish a hierarchy that clearly indicates which repairs should be top priority. Next, integrate your findings into your CMMS. This system serves as the backbone for organizing your maintenance tasks and monitoring the lifecycle of each piece of equipment.

Once you’ve categorized your equipment, create a Predictive Maintenance Schedule. Leverage the data collected from sensors and routine checks to anticipate when machinery might fail. By shifting focus from reactive to predictive maintenance, you’re able to address problems before they escalate.

Don’t overlook the importance of Resource Allocation. Evaluate your current resources – including technicians, tools, and inventory. You’ll need to ensure your team has the necessary parts on hand for critical repairs and that your technicians have the right qualifications to execute the tasks. A mismatch in resources can lead to further delays and increased downtime.

Remember to continuously Review and Adapt your maintenance plan. As operational conditions change, so too will your priorities. Make adjustments as necessary to reflect the ever-evolving nature of your equipment’s performance and the demands on your facility.

Executing and Monitoring Maintenance Tasks

Executing and monitoring maintenance tasks are the lifeblood of any effective maintenance strategy. Once you’ve assessed, categorized, and prioritized repairs, the focus shifts to the actual work. It’s about more than just ticking off items on a to-do list; it’s about ensuring that each task is completed efficiently, effectively, and safely.

Start by dispatching skilled technicians to handle the most critical repairs first. Empower them with real-time access to maintenance histories and manuals through mobile interfaces connected to your CMMS. This makes troubleshooting and repairs faster, reducing equipment downtime.

Track progress in real time by leveraging the reporting functions of your CMMS. These reports provide valuable insights into the status of ongoing maintenance work and can help you identify potential bottlenecks. For instance, if you notice that one task is consistently taking longer than planned, you can investigate and address the cause without delay.

Use key performance indicators (KPIs) to gauge the effectiveness of your maintenance activities. KPIs like mean time to repair (MTTR) and mean time between failures (MTBF) serve as benchmarks for maintenance efficiency. Aim to continuously improve these metrics as part of your ongoing maintenance strategy.

Balancing in-house capabilities with outsourced expertise can also enhance the execution of maintenance tasks. For specialized or complex repairs that go beyond your team’s expertise, bringing in external professionals can save time and reduce the risk of further equipment issues.

By staying on top of the execution and monitoring phases, you’ll keep your maintenance backlog in check and prevent the chaotic scramble that comes from unexpected equipment failures. Your goal is to create a loop of scheduled maintenance that keeps your operations running smoothly, without interruption.

Real-Time Monitoring Tools

- CMMS dashboards

- Mobile alerts and notifications

- Automated reporting systems

- Mean Time to Repair (MTTR)

- Mean Time Between Failures (MTBF)

- Planned Maintenance Percentage (PMP)

- Schedule Compliance Rate (SCR)

Remember, effective task execution is reliant on the clarity and frequency of communication within your maintenance team. Make sure everyone has access to the updated task lists and understands their role in the larger maintenance framework of your organization.

Preventing Maintenance Backlog from Piling Up

In combating the accumulation of maintenance backlog, proactive strategies are key. Opting for a preventive maintenance approach can significantly curb the snowball effect of accumulating repairs. This methodology involves regularly scheduled maintenance activities designed to prevent equipment failure before it occurs. By adhering to a stringent preventive schedule, you’ll minimize the risk of unexpected breakdowns and the subsequent pressure they add to your backlog.

Leveraging technology is also a crucial element in avoiding maintenance pile-up. Implement tools that offer predictive analytics; these systems utilize data and AI to forecast equipment malfunctions. By predicting potential issues, you’ll be able to address them swiftly, effectively sidelining the backlog before it takes root.

Here’s how you can further streamline your maintenance processes to ward off backlog:

- Standardize repair protocols: Having clear, established guidelines for tasks ensures consistency and speed in repairs.

- Invest in training: Equip your team with the knowledge to handle a range of issues, reducing the need to outsource for common problems.

- Prioritize tasks: Assess and assign urgency levels to tasks, dealing with the most critical ones first.

Inventory management also plays a pivotal role; maintain an adequately stocked inventory with all the necessary parts for essential repairs. This strategy avoids delays caused by waiting for parts to arrive, keeping your maintenance schedule on track.

Maintain clear communication among your team. Real-time updates on repair status and resource availability will prevent jobs from being overlooked or delayed. Utilize mobile communication tools so that your team can stay connected, no matter where they are on the floor.

By incorporating these strategies into your daily operations, your maintenance processes become more cohesive, efficient, and far less likely to allow backlog to accumulate. Remember, an ounce of prevention is worth a pound of cure – particularly when it comes to equipment maintenance.

Conclusion

Mastering your maintenance backlog is within reach when you embrace a proactive stance. With preventive maintenance and predictive analytics at your side, you’re equipped to foresee and address potential issues before they escalate. Remember, a streamlined approach, coupled with consistent training and clear communication, is your ticket to operational excellence. Keep your inventory ready and your tasks well-prioritized to ensure that your maintenance team operates like a well-oiled machine. Stay ahead of the curve and you’ll find that avoiding downtime becomes second nature.

Frequently Asked Questions

What is maintenance backlog?

Maintenance backlog refers to the accumulation of maintenance tasks that have not been completed as scheduled. It is usually a result of unexpected breakdowns, scheduling errors, or resource allocation issues.

How can one prevent maintenance backlog?

To prevent maintenance backlog, companies can adopt a preventive maintenance approach, use predictive analytics to forecast equipment issues, streamline maintenance processes, standardize repair protocols, provide thorough training, effectively prioritize tasks, and ensure a well-stocked inventory.

Why is preventive maintenance important?

Preventive maintenance is important because it helps organizations to avoid equipment failures by performing maintenance tasks proactively, based on a scheduled plan, rather than reacting to breakdowns after they occur.

How does technology help in managing maintenance tasks?

Technology aids in managing maintenance tasks by enabling the use of predictive analytics and maintenance software. These tools forecast potential equipment malfunctions and allow for better scheduling and tracking of maintenance activities.

What role does communication play in maintenance management?

Clear communication among maintenance team members is crucial to ensure that tasks are not overlooked or delayed. It facilitates the coordination of schedules, the sharing of important task-related information, and the prompt reporting and addressing of issues.